Swenson Civil Engineering Building

Project Overview

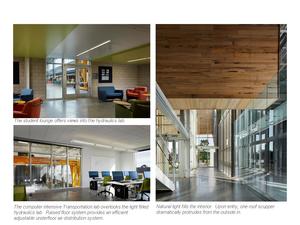

The Swenson Civil Engineering at the University of Minnesota Duluth is a two-story structure wrapped around double-height laboratories. The program called for 35,300 s.f. of space for instructional, research, and administrative functions. Spaces include faculty offices, student workspaces, classrooms, and centrally located structural and hydraulics laboratories.

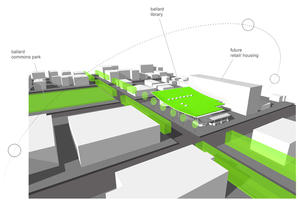

The building is located on the north end of campus, adjacent to an existing engineering building. Engaging the adjacent building and responding to existing pedestrian patterns presented challenges. The site sloped significantly from east to west, while access was required in both locations. The project team successfully designed a building that seamlessly engages the adjacent structure, reinforces existing circulation patterns, and mediates grade changes.

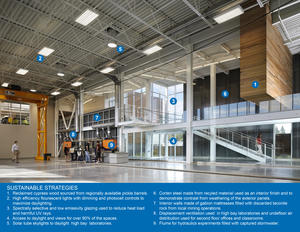

Designed to display systems as a pedagogical tool, the building showcases structural and mechanical processes and stormwater management techniques. It acts as a working classroom where design plays an integral educational role, and civil engineering processes are illuminated.

Sustainable strategies were incorporated into the design process and aesthetics. The University and State required that the building meet LEED Silver standards. The University encouraged incorporation of sustainable principles to foster development of civil engineers as responsible environmental stewards. The final design achieved LEED Gold certification, coming within four points of Platinum.

Design & Innovation

Sustainable principles were an integral design impetus. As an educational facility whose curriculum directly impacts the natural environment, it became apparent that the building could educate civil engineers on sustainable principles. This notion of building as pedagogical tool became a guiding concept.

Since the site drains into a protected trout stream, storm water management was a key ecological consideration. Elements of this system became prominent features articulating building processes and fostering understanding of sustainable design.

Sustainable principles were also reflected in material choices. The palette highlights the inherent beauty and durability of natural materials, reducing the need to maintain finished products. The use of regional materials provides a tangible and symbolic connection to local/regional economies.

The University developed an initial program based on anticipated needs. The design team administered questionnaires to streamline the requirements of each space. The open, flexible spaces accommodate large and multiple functions. Although the scale of the structural and hydraulics laboratories is dictated by program requirements, resulting spaces accommodate opportunities for large-scale gatherings, eliminating need for additional program area. The incorporation of operable partitions and a bi-fold door facilitated the movement of equipment, while enabling the loading area to efficiently serve the entire building.

Regional/Community Design

UMD has a history of educating the community, while providing students with hands-on experience in sustainability. The new building continues this by overtly exposing sustainable systems and materials. The local mining industry inspired the use of materials. Steel and Cor-ten were used in their raw state, exposing fabrication techniques. Taconite, local stone mined for its iron content, was used in both rock and iron pellet state.

The structural laboratory houses one of few local strong wall and floor systems. Local engineering professionals use the facility when available for their own research. This open door approach is mutually beneficial, bringing in local professionals that offer students hands-on experience, growth, and networking. The new facility and program will provide the Duluth market with locally educated civil engineers, a dire need in a state with many infrastructure shortcomings.

Over eight bus routes connect the campus to the community, emphasizing public transportation as a viable transit option. With over 30% of the student population housed on campus, and many others housed within one mile of campus, very few students use single occupancy vehicles.

The site selection placed the building over an existing parking lot, with no new parking stalls added.

Metrics

Land Use & Site Ecology

The design addresses a number of environmental quality issues affecting local and regional communities, including stormwater management, on-site ecosystems, and light pollution.

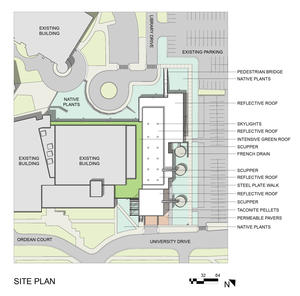

Seventy-three percent of the site is devoted to pervious materials and landscaping, reducing site detention requirements. A portion of these surfaces cover an area previously occupied by an impervious parking lot. An extensive green roof with native plants covers 22% of the roof, reducing stormwater rates and filtering impurities.

Sixty-two percent of the site is landscaped with native and adapted species, including a rain garden and prairie field. This results in the creation of small ecosystems conducive to sustaining local wildlife.

The site straddles two watersheds, one of which is a designated trout stream that is protected by the State. The stormwater system design was therefore required to comply with strict standards.

Stormwater is directed from the roof to three scuppers and into above-ground cylinders filled with rocks for filtering. Stormwater eventually makes its way to a French drain system of underground water storage pipes for retention.

The site lighting is minimal, and all fixtures are equipped with full cut-off optics. In addition, the maximum candela of interior light fixtures falls within the building envelope.

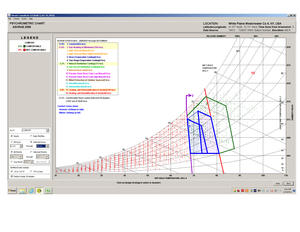

Bioclimatic Design

Although site selection was predetermined, site and climatic conditions informed the placement of key spaces within the building. The harsh winter climate, coupled with minimal building use during the summer months due to University scheduling, was the key factor in the final building design.

With a limited amount of usable site area, due to campus circulation concerns, the building was placed to utilize the entire north and west exposure of the existing adjacent building. From this connection, the civil building benefits from a significant reduction in exposed surface area. The buildings are also connected into the network of interior campus corridors, allowing students to access buildings without exterior entry, limiting cold air entering the buildings.

A majority of the occupied spaces are located on the buffered south perimeter of the building. The large open entry and stair are located along the north façade, allowing reduced temperatures within this transitional space. Clerestory windows line the south exposure of the large open hydraulics lab, allowing warm sun to penetrate and heat the space. Occupied spaces on the north utilize narrow window bays and solartubes to allow daylight and views, while retaining as much high R-value wall cavity as possible for heat retention.

Light & Air

The placement of glazing required careful consideration. Artificial lighting reduction and human health and comfort necessitate daylighting. However, in a harsh winter climate glazing must be used strategically to reduce heating loads. This resulted in a majority of the large expanses of glazing being used along transition spaces, which have a lower heating set point. These transition spaces acted as buffer zones to filter daylight into the building. In addition, solartube skylights were used extensively to maximize daylight, while retaining a high thermal value envelope. South-facing clerestory windows provide daylight and solar heat gain. No operable windows were provided, because the building is unused during summer months, the only season where passive ventilation would be beneficial.

Glazed views of the campus and natural landscape are provided in every occupied space. The best views serve the arterial corridors and the two large open stairs. Within the large entry stair and hydraulics lab, occupants are exposed to views of the oversized scuppers. During rain events, the scuppers activate the site by streaming stormwater into a series of Cor-ten drums. Connectivity between the building and site expose students and visitors to a variety of experiences.

Metrics

Water Cycle

Through integrated use of permeable paving, rain gardens, and an underground storm water retention system, 90% of the average precipitation is captured and treated on-site. Innovative roof drainage design allows for this high level of retention. Conventional roof drainage funnels water directly into the storm sewer system, whereas this building slopes roofs to a system of scuppers, directing all roof water into the large entry underground French drain and rain gardens along the building perimeter. An intensive vegetated system covers 23% of the roof, reducing overall stormwater impact.

Water conservation is achieved with dual-flush water closets, low-flow urinals and lavatories, and no landscape irrigation. All plantings are native or adapted, eliminating the need for irrigation.

The French drain acts as a large wet sedimentation basin to capture stormwater runoff from the roof and adjacent sidewalks. The system utilizes the permanent storage volume to cool stormwater for temperature control, providing quiescent retention to allow settling of sediment. The underground system allows infiltration to reduce runoff volume. Retained storm water is pumped into the building for use within the Hydraulics laboratory experimental flume. The 7,500-gallon flume is refilled at minimum 3 times a year.

Metrics

Energy Flows & Energy Future

Through the building siting, massing, orientation, envelope and daylighting, the design attempts to passively accomplish as much energy savings possible prior to systems selection. In the high-bay laboratory spaces, the displacement ventilation system provides improved thermal comfort, IAQ, and improved energy consumption. An underfloor air distribution system used throughout the classroom and office spaces provides improved ventilation effectiveness and increased economizer operation, as well as a high level of user control. This building does not have fossil-fuel-consuming equipment. The building connects to the existing campus heating and cooling plants. Centralized plants have an economy of scale advantage when changing to future fuel sources.

Combinations of strategies were used to reduce peak electrical demand. Occupancy and daylight sensor control of lighting along with abundant use of daylighting provides the largest savings through elimination of lighting. The design also utilized glazing area, orientation and properties to minimize heat loss. Variable-air-volume fans with variable-frequency drives cut down tremendously on HVAC system energy loads. In addition, digitally addressable lighting components allow for reduction and simplification of control wiring.

This building type is not covered in the Energy Star tool; however this building exceeds the Minnesota Sustainable Building Challenge 2030.

A recent audit of the campus-wide building meters has revealed inaccuracies in the building energy use data. The University is currently in the process of recalibrating their campus meters to provide accurate data and determining a correction factor to be applied retroactively to previously compiled data. Therefore at the present time, accurate building energy use measurements are unavailable.

Metrics

Materials & Construction

The building materials were selected to showcase the beauty of locally available raw, natural, unaltered materials that provide the basis for a sustainable building product and serve as a teaching tool. These materials include Cor-ten steel, pre-cast and poured-in-place concrete, CMU, reclaimed local taconite rocks, reclaimed wood, and local tamarack wood. Chemicals and treatments were not used on these unaltered materials, reducing manufacturing impact and health concerns. All non-occupied, transition, and laboratory spaces have exposed ceilings, structure, and systems. All spaces except offices have exposed floors. The use of raw and locally available products resulted in over 20% regionally harvested and manufactured materials and over 30% recycled materials.

Over 95% of the total construction debris was diverted from landfills. The choices made in building materials and methods made this significant amount of savings relatively easy. Natural unaltered building materials provided a high level of recyclable waste, while items such as the Cor-ten rainscreen panels were designed to utilize a full sheet size, eliminating cut waste.

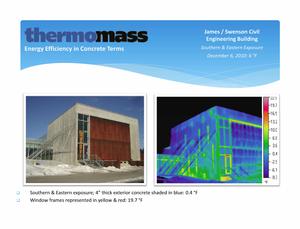

A high performance building envelope, including high R-value roof and walls, a ventilated rainscreen system, and high performance spectrally selective glazing, help insulate the building and reduce heating demands.

Long Life, Loose Fit

The building was designed to provide spaces that are open, flexible, and adaptable to multiple configurations.

The hydraulics and structural laboratories accommodate large scale experiments along with equipment necessary for transport. The resulting spaces are large and open, allowing them to accommodate large scale functions for the department and overall college.

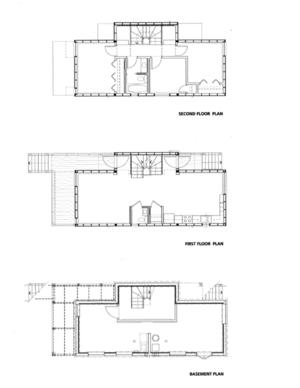

Two second floor classrooms are divided by an operable partition enabling them to expand for larger gatherings. Systems furniture was installed in offices to enhance versatility and facilitate future adaptation of spaces to multiple configurations. Raised access flooring systems in classrooms and offices allow for reconfiguration of diffusers and power sources to accommodate various layouts.

As typically long-lived institutions, universities generally commission buildings designed for long term usage. It is therefore unlikely that the building will serve a function not related to the University. However, given the open nature of design and flexibility of spaces, it could easily be adapted to other education-related uses.

Building materials were selected to showcase the inherent beauty of natural materials. The resulting material palette of Cor-ten steel, reclaimed wood, concrete, and taconite rocks is strong and durable, and intended to last the life of the building and evolve naturally over time.

Collective Wisdom & Feedback Loops

Since the Civil Engineering program is new to the University, key stakeholders were not yet in place during the design process to provide input. As a result, design parameters for complex equipment were not finalized until program personnel were hired during the construction phase. The design evolved to incorporate major programmatic and equipment requirements while providing flexibility for future refinements. The design team, University, and contractor worked closely to coordinate these elements during design and incorporate final requirements during construction. While challenging, this process resulted in a very successful outcome.

Sustainable measures were closely monitored throughout design. UMD requires all new buildings achieve a LEED Silver certification. The design team strove to exceed this requirement and provide the most sustainable building within budget and schedule. The team worked collectively to reduce materials, improve efficiency, and improve health and comfort of the occupants.

Evaluation of the actual performance is ongoing by the design team and University, since a full class schedule did not occur until Fall of 2010. A six month user survey was recently given and all issues were resolved satisfactorily. In December 2010, thermal imaging of the building was done to further evaluate the performance, with favorable results.

Other Information

The AE team and University worked together to keep the project within budget. For a university laboratory building, the facility was constructed on a relatively modest budget of $334/square foot while earning a LEED Gold certification. The building was designed using passive sustainable strategies with a few innovative systems such as displacement ventilation in the high bay laboratories and underfloor air distribution in the offices and classrooms. Systems were selected based on their performance, as well as up front costs. Those with the highest return on value within a 5-year period were selected for use.

The energy modeling for the building estimates an annual $21,000 savings, or 35.6% reduction over the baseline model.

Predesign:

During predesign, three alternative methods were considered for providing the required space for the civil engineering program while minimizing new construction. These included space reallocation, remodeling, and new construction. It became apparent that reallocation or remodeling of existing spaces would be inadequate to meet the program needs.

Due to its proximity to existing engineering buildings and limited availability of suitable locations, a site directly adjacent to an existing engineering building was selected. The design team investigated various massing and spatial configurations. Options were evaluated based on economic criteria, programmatic requirements, and sustainable project goals. The resulting layout takes advantage of shared exterior walls to reduce exposure and minimize energy heating costs.

The layout of spaces reinforces existing pedestrian circulation routes. A corridor on the west wraps the existing building, linking it to the new while providing an attractive new front. A bisecting east-west corridor accommodates campus circulation while mediating a significant grade change across the site.

The program requirements necessitated that a portion of the building footprint and site encroach on an existing impervious parking lot. Although parking spaces were lost, the development of the site incorporated a prairie field and permeable surfaces contributing to reduced stormwater runoff.

Design:

Sustainable principles guided the development of the design. State and University requirements dictated that the building meet LEED Silver standards. During schematic design, the project team used the LEED rating system to identify potential sustainable design strategies.

A commissioning agent was introduced during design development to assist the design team and contractor in efforts to ensure that building systems perform as modeled. After design completion, the project was submitted to the USGBC for evaluation of LEED design credits.

As various sustainable design strategies were incorporated, the notion of building as a pedagogical tool took shape. Various systems were exposed and articulated in order to educate future civil engineers on building systems and materials.

Materials were researched and evaluated based on economic feasibility and ability to contribute to sustainable design goals. This research informed the decision to incorporate and highlight natural materials for their inherent beauty and durability. Research was conducted to identify local materials that would provide a symbolic and tactile connection to the region. Taconite, a locally mined stone, was used on site in pellet form as a permeable surface, and in rock form as a stormwater filter. Taconite rocks were also used as fill for gabion baskets, forming a feature interior wall.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Design Architect | Carol | Barney | Ross Barney Architects | Chicago, IL |

| Architect of Record | Brian | Morse | SJA Architects | Duluth, MN |

| General Contractor | Deborah | Aldrich | Stahl Constrution Company | St. Louis Park, MN |

| Landscape Architect | Tom | Oslund | Oslund and Associates | Minneapolis, MN |

| MEP/FP Engineers | Bill | Schweitzer | Dunham Engineering | Minneapolis, MN |

| Structural Engineer | Craig | Bursch | MBJ Consulting Structural Engineers | Duluth, MN |

| Civil Engineer | Preston | Tripp | MSA Professional Services | Duluth, MN |

One of the few instances of a search for some kind of expression whereby the devices of shedding water or of getting large pieces of equipment in and out of the building become part of the signature expression of the building.

It’s a school for civil engineering and it’s a demo lab for civil engineering.

It’s also an example of wedding together buildings that perform well, but also are aesthetically rich and culturally useful, beneficial, and beautiful in their own way.

It has an honest expression of the materials. It is very clear what this building is made of.

Seventy-seven percent energy reduction below its baseline in that severe climate is impressive.

The other thing that excited is that it was a building that was being creative in its architectural expression in a way that made it more sculptural and very bold and solid like the sciences being studied within the building.