New Orleans BioInnovation Center

Project Overview

This non-profit lab/office facility serves as an incubator for biotech startups; helping ideas conceived locally to become local jobs and industries. The New Orleans BioInnovation Center (NOBIC) is a four-story, 64,000-square-foot structure adjacent to New Orleans’s historic French Quarter, downtown university campuses, and the Treme neighborhood. Built on a brownfield site, this LEED-Gold research facility is designed as ‘urban acupuncture’, a modest project that helped trigger the revitalization of a neighborhood, generating over 200 jobs. The program includes a flexible 100-person conferencing center, breakout spaces, and a 2,000-square-foot café. The design reinterprets vernacular regional climate-responsive strategies—the slatted shutter, the landscaped courtyard water feature, the sheltered porch—to provide a facility that is both of its place and of its time.

Key challenges:

• Laboratory buildings are among the most intense users of energy of all building types driven by the intense conditioning of outdoor air used to ensure occupant safety—an extreme challenge in the hot and humid Gulf South. By empowering user choice over temperature and ventilation at a granular scale, NOBIC achieves a measured energy use 1/3 that of a typical lab.

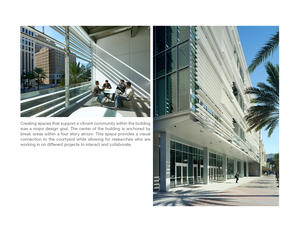

• Accommodating a wide range of potential lab users while promoting informal interactions that drive creativity.

Design & Innovation

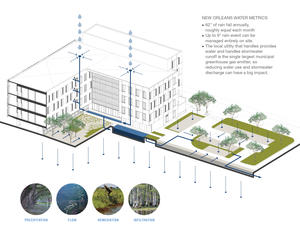

Building a laboratory building in post-Katrina New Orleans raises three challenges: how to create a low-energy lab in a hot humid climate, handle water wisely in ways that connect people to their environment, and provide a modern, sleek facility that allows entrepreneurship to flourish in a resilient new economy.

The client challenged the team to deliver a facility that was not just functional, but as beautiful and distinctive as the city around it. The site—a former brownfield wedged between the city’s most prominent boulevard and a low-income housing project—reinterprets the architectural traditions of the nearby French Quarter.

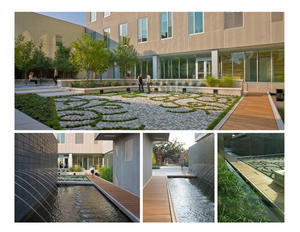

The flow of water through the site is handled as a design opportunity rather than a plumbing problem. A ‘working water feature’ captures rainwater and diffuses it to plants and soils on site, evoking the flow of water in the regional ecosystem. The water feature is also fed by the AC condensate (up to 20,000 gallons per week!), which provides all landscape irrigation on site.

The incubator program provides a place for local ideas to turn into local jobs. By complementing private labs with shared equipment and amenities, NOBIC gets the most function and inspiration out of the least material.

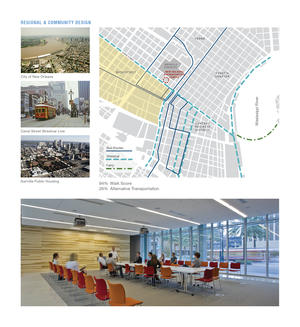

Regional/Community Design

New Orleans has suffered from a decades-long population decrease as talent and jobs have gone elsewhere. In its first 3 years of operation, this facility has hosted over 40 startups generating over 200 jobs at all skill levels.

New Orleans holds an outsized place in the nation’s cultural imagination--steeped in history and built on improvisation. This project helps local innovators develop new businesses in a very New Orleans way—with a spatial organization that promotes chance meeting, social interaction, and improvisational collaboration, inviting busy people to linger centered on the porch or the garden. The informal ties between people are key to the city’s resilience.

While many ‘incubator’ facilities are located in suburban office parks, NOBIC is distinctly urban, with major streetcar and bus lines stopping at its front door, steps from collaborating institutions and, most importantly, right on major Mardi Gras parade routes. Onsite parking is limited to the minimum required by zoning, while adjacency to 5 public transit lines, onsite accommodations for electric vehicle charging, and preferences for high-efficiency vehicles within limited onsite parking complement these strategies for urbanity. With a WalkScore of 94 and nearby housing under redevelopment, a walkable all-income live/work environment is becoming a reality.

Metrics

Land Use & Site Ecology

Close to the mouth of the nation’s largest river, but with alluvial soils that begin to sink as soon as they are drained, subject to intense rain, flooding, and hurricanes; New Orleans has been described as “a bad site but an excellent situation.” The same is true of the project site—a brownfield with excellent urban density, adjacencies, and access to public transportation, but with contaminated, poorly draining soils prone to movement and subsidence.

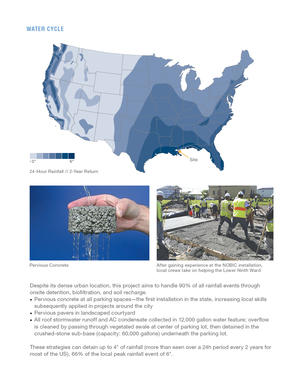

After brownfield cleanup was complete, the NOBIC project team selected a lightweight structure and cladding on piles, and a landscape/soil/water system that uses slowly percolated rainfall to recharge the soils, minimizing subsidence. Onsite parking (the minimum required) was provided with the first pervious concrete installation in the state, built on top of 18” of crushed stone, which provides stormwater storage, biofiltration, and recharge for the entire site. This is fed by rainwater from the roof, cushioned in the courtyard water feature, filtered by marsh plants. This is the regional water/plant/soil ecosystem in microcosm, connecting people back to place.

Bioclimatic Design

The New Orleans climate alternately delights and exasperates: mild winters, hot humid summers with little wind, abundant sunshine punctuated by periods of intense rainfall and the occasional hurricane. Less than 1% of the hours in a typical year fall in the range of temperature and humidity required by the NIH for biotechnology labs, and 68% of the hours are either too hot or too humid. The provision of high air-change rates and once-through ventilation air with tight temperature and humidity control dominates lab building energy use, dwarfing skin loads.

The building form is configured to provide a protected courtyard following French Quarter precedents. The glazing choices allow a strong connection to the city and the landscaped courtyard while limiting solar gain. While the building as a whole has a window/wall ratio of 35%, glass is deployed to maximum effect on the primary street façade and lobby atrium with their social areas on each floor. Playfully deployed louvers allow the southwest-facing Canal Street façade to be 63% glass yet have the summer solar gain of a façade with only 20% glass, while the other zone of extensive glazing (the atrium) connects social spaces to the courtyard via a northeast exposure.

Light & Air

The standard lab unit provides both daylight and views, while also providing lower-light entry zone for locating light-sensitive equipment such as microscopes. All meeting and common areas have extensive views to the outdoors, as are the dedicated offices facing the primary boulevard.

The safety standards of some lab tenants require that air be flushed through labs at rates up to 10 air changes per hour, and lofted far away from the building. They also require controlled temperature and humidity levels for reproducible experiments, making operable windows for labs generally inappropriate. By using the conditioned return air from offices as a dilutant for lab air supply, conditioned comfort can be provided to office areas at negligible energy cost. Adjacent sheltered balconies provide for connection to climate.

Each cellular lab is provided with independent control of airflow and temperature, allowing each researcher to choose the ventilation level appropriate to their kind of research, and schedule ventilation setbacks when labs are unoccupied. In addition, a ‘panic’ button is provided which takes room flush-out and fume hood exhaust rates to maximum. Careful design and modeling of the air distribution system allows lower air change rates to be employed without compromising safety.

Metrics

Water Cycle

Located in a city that owes its existence to a river and its near-destruction to flooding, it was essential that the design embrace the theme of living with water. All phases of the water cycle were treated as a design opportunity, from dealing with the moisture that hangs heavy in the air on a summer day, to the frequent, intense rains, to the flow of surface water and its re-percolation into the city’s heavy soils.

While most parts of the country deal with an inch or two of rain in a 24h period, the Gulf Coast frequently receives up to 6 inches in a day, sometimes up to 2 inches in a single hour. The project feeds all rainfall from the roof into a prominent water feature whose depth fluctuates with the rains, allowing for biofiltration through water plants, then overflowing into a vegetated swale, detention in the parking lot sub-base, and percolation back into the soils. Simulations project that stormwater will leave the site only once every 20 years. The water feature is also fed by the AC condensate, which provides all landscape irrigation (the only use currently allowed for captured water by state regulation).

Metrics

Energy Flows & Energy Future

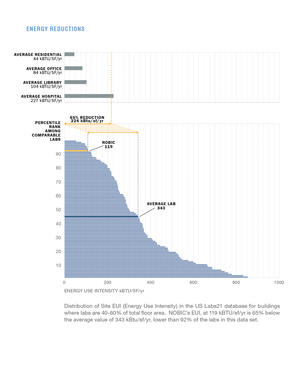

This project uses less energy per square foot than 89% of the buildings in the Labs21 benchmarking database of over 400 lab/office buildings nationally, 67% below the median EUI (343kBtu/sf/yr). The actual utility bills for the initial 12 month period (117kBtu/sf/yr) closely track that projected by computer simulation (119 kBtu/sf/yr). This savings of 224kBtu/sf/yr is like making a net-zero building of almost any other building type.

This level of verified performance has been achieved through a combination of an efficient building skin employing strategically deployed glazing with solar controls, highly targeted controls of airflow, temperature, and lighting for virtually every space, and an efficient central plant. It is reinforced at the operations level by fine-grained energy and comfort monitoring. Each ~1000sf lab + support area unit is individually metered, enabling the building owner to track and compare lighting and plug load consumption, identifying best-practice high performers. 73% of site energy use is electricity, with purchase agreements in place for carbon-neutral sources, and the roof has been made solar-ready with attachment footings and conduit in place for future PV.

Metrics

Materials & Construction

The first strategy in reducing materials impacts of any project is to construct only as much building as you need. At the start of project programming, the design team developed strategies for shared use between tenants to increase collaboration while decreasing building area. This produced spaces that function for multiple program needs as well as multiple users, resulting in a smaller building and reduced material use.

A lightweight steel structural system was selected to minimize foundation requirements in a region with two miles of mud before bedrock. The exterior cladding system balanced the goal of minimum material while providing durability and storm hardening along with low maintenance. The design team persuaded a regional fabricator to manufacture a hybrid system of a thin (2”) precast concrete wall panel stabilized by a light-gauge steel interior frame. The project convinced local concrete suppliers to be the first to employ high recycled content mixes, and had local crews trained for the first installation of pervious concrete in the state.

79% of onsite construction waste was diverted from landfill, in part thanks to innovative relationships with waste handling firms, including one that began new diversion programs as part of the project.

Long Life, Loose Fit

The building is designed to promote and thrive on change. Plan layout includes a mix of ‘dedicated’ lab and ‘office’ spaces and an almost equal area of ‘flex’ spaces with infrastructure to accommodate lab use but which can be alternatively built out to offices according to the needs of the tenants.

Key building structure and shell components have been designed with a 50 – 100 year service life, with detailing at all building penetrations being designed for ‘defense in depth’ with multiple layers to keep wind-driven rains out of the building. Structure, glazing, and water-handling systems are designed around 100-year storms. The primary building structure (steel) is designed for easy dis-assembly and recycling.

Collective Wisdom & Feedback Loops

It is a tenet of integrated design that sustainable design choices have more impact and less cost when incorporated early in a project—so eyebrows were raised when the Owner announced a desire to pursue LEED certification as the project came off hold months after completion of construction documents. Conventional wisdom would say it was too late. But because the project team employed sustainable design principles throughout the design process, the project was able to achieve LEED Gold certification and energy consumption lower than 92% of comparable lab buildings with modest alterations to the documents.

The three-month optimization exercise is described in further detail in the ‘Project Economics’ section.

After substantial completion and occupancy of three floors of the four-story structure, the design team and commissioning agent initiated a ‘continuous commissioning’ exercise, monitoring energy consumption, systems, and comfort performance, identifying a substantial number of items that had cropped up after initial commissioning. This allowed energy and comfort performance to be further tuned. The project is now part of a commitment of all team members involved to long-term engagement and learning. The team continues to engage occupants and operators as the tenant mix changes, learning as they go.

Other Information

After construction documents had nominally been completed, the Owner and design-construction team entered into a 90-day exercise exploring opportunities for further enhancements in environmental impact and performance. A brainstorming exercise developed a list of 21 opportunities for investigation. Computer modeling helped sort the opportunities into four categories: high-cost items with good payback or schedule impact, low-cost items with big impact even if payback was negligible, high-cost items with poor payback or low impact. The project proceeded with items in the first two categories. Treated as a group, this package of upgrades had a price tag equivalent to less than 2% of the project cost, but simple payback of less than 3 years.

The project was delivered in a Construction Management framework, with Owner, Architect, Engineers, General Contractor, and key Subcontractors all at the table throughout the design process. This approach allowed for realistic feedback on constructability and cost throughout the design process. While it is widely appreciated that decisions made in pre-design and early design phase have the greatest impact on environmental performance at least cost, the experience from this project shows that every stage matters, and every stage is an opportunity for improved performance.

During pre-design, key performance goals centered on flexibility, ease of adaptation to new tenants with new technical requirements, durability, energy and water costs, and providing an excellent indoor environment (daylight, views, air quality).

Like many projects with multiple funding sources and clients, this project went through a number of starts, stops, and re-starts. These pauses actually worked in favor of the project’s environmental performance, allowing for reflection and re-consideration. The biggest round of reconsiderations occurred after the project, having reached “100% Construction Documents” phase, went on hold for over a year as construction financing was assembled. As it came off hold, revised cost estimates indicated that the project was under budget, and the team was given 60 days to develop strategies that would further improve environmental performance while accommodating changes to anticipated tenant requirements, code updates, and a new Owner commitment to pursue LEED certification. A total of 21 measures were identified and evaluated. During this process a number of measures emerged that had little or no impact on the “percent below ASHRAE” projected energy use rewarded by LEED that could have big impacts on actual energy use. Key among these was advanced sub-metering and occupant controls for temperature and airflow in each lab unit. It was necessary to develop two parallel energy models—the model following the format expected for LEED certification, and the one that reflected how we thought the building would actually be occupied and used. This second model has been carried forward as the building was occupied and further build-outs proceeded.

Since construction was phased, with the top floor being empty shell space at initial building opening and then finished over the subsequent months, all members of the team were frequently on site during the first year. This allowed for an unusually high degree of interaction during this crucial “shake-down” period when bugs are worked out and building operations staff masters the finer points of complex building systems. At their own expense, the Architect, Engineer, and Commissioning team members continued to track performance and tune the building, using it as a learning opportunity.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Principal in Charge | Mark | Ripple, AIA, LEED AP BD+C | Eskew+Dumez+Ripple | New Orleans, LA |

| Director of Design | Steve | Dumez, FAIA | Eskew+Dumez+Ripple | New Orleans, LA |

| Director of Sustainability | Z | Smith, AIA, LEED AP BD+C | Eskew+Dumez+Ripple | New Orleans, LA |

| Project Architect | José | Alvarez, AIA, LEED AP | Eskew+Dumez+Ripple | New Orleans, LA |

| Project Manager | Jessica | Stumpf | Eskew+Dumez+Ripple | New Orleans, LA |

| Project Manager | Cynthia | Dubberley, AIA, LEED AP BD+C | Eskew+Dumez+Ripple | New Orleans, LA |

| Principal | Robert | Bruckner | nbbj | Seattle, WA |

| Lab Planner | Dan | Dennison, AIA | nbbj | Seattle, WA |

| Landscape Architect | Daly-Sublette Landscape Architect | Kenner, LA | ||

| Civil/Structural Engineer | Morphy Makofsky Inc. | New Orleans, LA | ||

| MEP Engineer | Newcomb & Boyd | Atlanta, GA | ||

| General Contractor | Turner Universal | Nashville, TN | ||

| Local General Contractor | Gibbs Construction | New Orleans, LA | ||

| Project Manager | Adams Management | Rome, GA |

We like the floor plan and purpose of the building and admire the shading system. The building is simple, elegant, and beautiful. The shading system is the most striking part of the building. It also demonstrates loose fit: the entire plan was modular and the building has a variety of clients floating in and out, so the plan is loose fit in action. They have demonstrated very high levels of energy performance, especially given a very challenging climate. This is difficult to accomplish in New Orleans. The façade treatment had thoughtful and well-proportioned shading on the SW elevation.