Manitoba Hydro Place

Project Overview

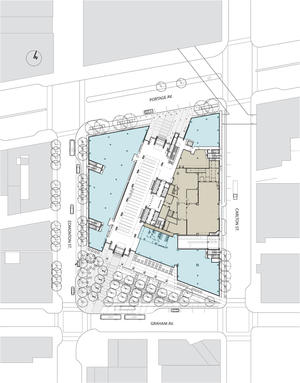

Manitoba Hydro, the primary energy utility in the province of Manitoba, set ambitious goals for its new headquarters, including energy efficiency, urban revitalization, and a supportive workplace. The 700,000 square foot, 22-story office tower occupies a full block in the center of Winnipeg, a city that is well known for its extreme climate and a downtown in recovery from severe economic downturn in the late 20th century.

The site was selected for its proximity to the city's transit system and a network of raised walkways that connects buildings in the downtown core. The form and massing directly respond to the climate, while the architecture works to revive the city's former 'Chicago-scale' urban spirit. The relocation of 2,000 employees from 15 suburban offices to the downtown also signifies the corporation's shift to a collaborative culture and a commitment to provide the community with a signature architectural image.

The design also visibly manifests Manitoba Hydro's commitment to environmentally responsible practices, achieving an unprecedented 64.9% energy savings by harnessing maximum passive solar, wind, and geothermal energy. To achieve the seamless integration of design and performance goals, Manitoba Hydro committed to following a formal integrated design process (IDP).

Design & Innovation

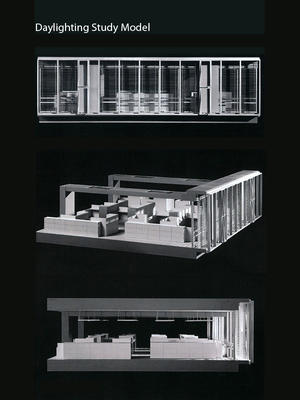

Manitoba Hydro Place introduces the next generation of sustainable, energy-efficient architecture developed under a formal Integrated Design Process. The design fuses time-tested principles such as massing, orientation, and exposed thermal mass with immediate digital analysis and computerized building management systems to create a climate-responsive design that relies on passive energy while delivering design excellence and, most importantly, fostering the wellbeing of employees.

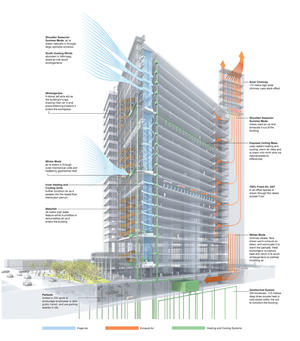

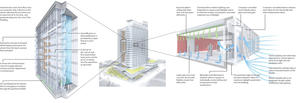

Every part of the building relates to the whole. The signature capital 'A' comprises twin 18-story office towers set on a 3-story, street-scaled podium. The podium, bisected by the Public Galleria and clad in masonry to connect to the city's historic fabric, creates a sheltered route through the full city block. The towers converge at the building's north end to minimize north-facing surface area. To maximize solar and wind exposure, the towers splay open to the south, where they are clad in low-iron glazing to minimize the mass of the building in the urban context. The solar chimney is both essential to the passive ventilation strategy and for presenting the building as a new urban icon. The south-facing winter gardens feature 24-meter-tall waterfalls that humidify or dehumidify (depending on the season) incoming air and animate the space as kinetic sculpture.

Regional/Community Design

The site was specifically selected to maximize energy efficiency, sustainable technologies, public transport availability, and urbanization. Two significant public spaces were created to enrich the downtown: an outdoor park in the south portion of the site and a publicly accessible, three-story-high Public Galleria that runs the full length of the podium base to connect the north and south entrances and provide a new interior, barrier-free gathering space that can accommodate over 1,000 occupants for concerts, farmer’s and Christmas markets, and special events.

The building’s plan organizes vertical neighborhoods around north and south atria to create a sense of community in the high-rise format. Atria feature connecting stairs that also act as spectacular viewing platforms to the city and horizon. Employees report loving their new work space and collaborative environment, and some individuals who intended to retire have chosen to extend their employment.

With neither daycare nor a staff cafeteria, employees are encouraged to patronize city restaurants and services, contributing to a steady strengthening of the downtown economy.

Fifteen hundred free parking spots were written out of the design as employees embraced public transit incentives. Over 2,500 visitors have toured the building and pedestrian counts are up in the downtown.

Metrics

Land Use & Site Ecology

Manitoba Hydro Place occupies a previously underutilized site, formerly occupied by several vacant buildings. The vacant buildings were carefully deconstructed, with 95% of the components either recycled or reused. For example, old-growth Douglas fir beams were milled and reused in the new building for soffits and benches. The site had been designated a brownfield, so soil remediation was required to remove patches of hydrocarbon contaminants.

The two towers of the building sit on a street-scaled podium. Structural and glazing systems emphasize lightness and transparency to reduce the impact of the mass on the surrounding neighborhood. Large-scale entrance canopies protect against prevailing winds and provide shelter for pedestrians.

Green roofs cover the podium roof, providing a dramatic increase in landscaping compared to the hard-surface parking lots and tar roofs of the original site. All green roofs employ native plant species, irrigated by rainfall or, during drought conditions, by condensate collected from the building’s mechanical equipment. All plant species incorporated into the green roof are native to the region, and one of the green roofs is dedicated to the First Nations and was planted with sweetgrass in a traditional ceremony. An increased number of street trees and a grove at the site’s south park help create shade conditions at grade.

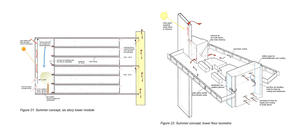

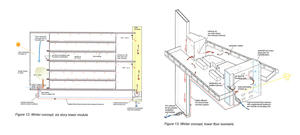

Bioclimatic Design

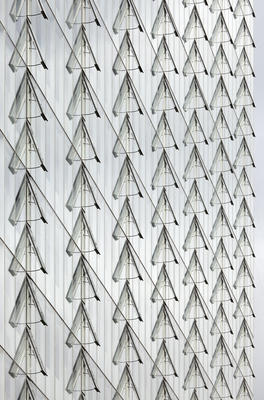

Site and climate analysis identified Winnipeg's unusual abundance of sunshine and dominant gusting south winds as opportunities to harness passive solar and wind energies. The team generated 15 massing options and tested three for optimal performance. The Capital A option provided maximum passive solar gains in winter and natural ventilation in the shoulder and summer seasons. Climate-responsive features include a high-performance building envelope and a massive geothermal system with 280 boreholes, each 125 meters deep). Three south-facing, six-story "winter gardens" act as lungs, with 24-meter waterfalls that humidify/dehumidify air entering the building. The concrete structure creates thermal mass to moderate extreme temperature swings. The advanced facade system ensures 100% fresh air and maximum daylight. Automated louvers and windows open and close in reaction to light and temperature changes, making the bioclimatic design visible to the city. A radiant slab between the double facades maintains minimum temperatures in winter and heat exchange with the geothermal field in summer. In the winter, the solar chimney draws exhaust air down to heat the parkade and pre-heat incoming cold air via the south atria. During warmer seasons, the solar chimney exhausts stale air from the building.

Light & Air

Beyond energy conservation objectives, the goals to provide 100% fresh air and maximum daylight reflect the owner’s commitment to the health and wellbeing of its greatest asset—its employees.

Narrow, 11-meter-wide floorplates ensure access to views and natural light. East and west tower facades are double-glazed with motorized windows on the exterior and single-glazed with manually operable, hopper-style windows on the interior. Large-format automated louvers within the double façade open and close throughout the day to minimize solar gain and glare. Louver blades at the top act as a light shelf, bouncing additional light onto the white ceiling.

Direct/indirect T5 HO fixtures are dimmable, equipped with daylighting and occupancy sensors, and are individually adjustable from the central building management system, allowing daylight harvesting for maximum efficiency and flexibility. Slightly lower overhead lighting levels reduce potential glare, and individual LED task lights at each workstation focus light where it is required most: on the work surface.

During shoulder seasons, windows open and supply air is drawn in passively by the solar chimney. Low-pressure, under-floor displacement air delivery allows for individual environmental control at each work station.

Metrics

Water Cycle

The roofs of the podium feature deep-soil intensive green roofs and create accessible, lushly landscaped terraces as an outdoor amenity for employees, while also reducing stormwater runoff and providing additional thermal insulation. Excess rainwater is held within the green roof tray system until the planting medium is ready to absorb it. Hydro Place employs an innovative approach to green roof irrigation. Excess condensate generated by the building’s fan coil units during the hot summer months is directed to large cisterns located in the building’s parking garage. When conditions warrant, this reclaimed water is pumped back up to the green roof and redistributed via an efficient drip irrigation system.

Waterless urinals and low-flow toilets and sinks are used throughout the building.

Energy Flows & Energy Future

The design aligns with Manitoba Hydro’s policies of energy-use reduction and clean power sources. It successfully establishes an exemplar of climate-responsive, energy-efficient design for large buildings in extreme climates. Since the first occupants moved into the building in December 2009, the building has exceeded the original 60% energy savings goal and is now targeting 64.9% energy savings. This is in large part due to the integrated design process, which ensured the rigorous integration of systems and operations, including radiant heating and cooling delivered through an exposed concrete thermal mass. The large geothermal field, high-efficiency condensing boilers, and efficient heating and cooling systems ensure that supply and exchange is utilized. A sophisticated building management system monitors internal and external environments to optimize lighting, solar shading, and heating and cooling loads while taking advantage of passive energy sources. User control of lighting in the offices, managed through desktop computers, is projected to save an additional 10%–15% in electrical lighting loads. As a crown utility and the main supplier of electrical energy in the province, Manitoba Hydro’s clean energy, hydro, and wind electric sources provide carbon-neutral power to the building.

Metrics

Materials & Construction

Durability, lifecycle costs, regional relevance, and health and wellbeing were critical factors in the development of the building’s materials palette. Locally quarried Tyndall limestone and locally sourced granites were chosen to reinforce Winnipeg’s urban fabric of masonry buildings and Manitoba Hydro’s relationship to the northern landscape. Embodied energy was a consideration in the selection of all materials.

Large portions of the structure were left exposed in order to increase the conductivity of the radiant concrete mass, and to reinforce the open loft concept. Douglas fir elements, the majority sourced from the buildings that previously occupied the site, are applied in key public spaces to introduce warmth and texture.

All interior materials meet low-VOC standards in order to provide a safe and healthy working environment. All carpet tile is made from 100% recycled materials. Color is used as an organizing element throughout the office spaces. The building core is painted red, running the full height of the building.

The towers’ exteriors are composed of extremely high-performance double- and triple-glazed unitized curtainwall panels. Curtainwall components were assembled locally to minimize costs and to facilitate quick and proficient installation and minimize delays due to the extreme climate.

Long Life, Loose Fit

The two towers that comprise the ‘Capital A’ were conceived as a modern interpretation of the ubiquitous 19th-century urban loft building. Each floor provides consistent large-span column free spaces, expansive glazing, and is characterized by a robust exposed structure to provide the flexibility of potential reconfiguring for new occupants well into the future.

Raised floor systems facilitate the inevitable office churn and minimize the time and cost of retrofits. All air distribution, power, plumbing, voice, and data are distributed through the raised floor system, easily accessed by peeling away the carpet tile and lifting the concrete floor tiles.

The building facades are organized around a typical five-foot planning module, allowing for a multitude of uses and potential wall configurations. Manually operable windows punctuate the exterior façade at 10 feet on center, ensuring that all spaces have access to individually controlled natural ventilation.

The Public Galleria at the ground floor creates a grand public space that links the crown corporation to the life of the downtown and in turn establishes a popular, public destination for informal gathering and a range of formal and festive events through all seasons.

Collective Wisdom & Feedback Loops

The project used an integrated design proces (IDP), outlined by the Canadian Government’s National Research Council as IDP-2000, to design and develop ideas. Creating 15 initial schemes, then narrowing these to three for further development, the team used the goals of specified energy targets and urban renewal gestures as measures for the success of each design. Ongoing charrettes after the final project selection coalesced the preliminary strategies into real systems. The highly integrated nature of some of the elements, such as atrium water features and the buildings humidification/de-humidification facilities, are a direct outcome of these charrettes. By merging age-old and proven techniques with metered and controlled building components, energy savings potential and design quality were met and exceeded throughout the building. Further, the commissioning process involved key consultants maintaining a presence through monthly meetings and a distance-monitoring program with the building management system. All visible systems were scrutinized, tested, modified, and refined by every specialist on the team (including the architects) to ensure that every element was synchronized to the whole and harmonized in proportion, form, and scale.

Other Information

Finance & Cost

To ensure that the energy objectives were not compromised at the expense of cost and design, a customized business-case model was developed by Manitoba Hydro to balance all goals for design, energy/sustainability, and cost in balance. By inserting sustainability/energy goals into the conventional design/cost model, the green agenda became an equal priority at a time when green objectives were often quickly abandoned due to cost. This was then anchored by design excellence goals identified by the architects for supportive workplace, signature design, and urban design.

Cost Data

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $278,000,000

Manitoba Hydro delivers one of the most successful demand-side management programs in North America. The program utilizes a number of economic screening tests as agreed upon by the governing body of the utility, the Public Utilities Board. These tests include a total resource cost test, a rate impact measure test, a utility impact measure test, and most important, a lifecycle cost test. The building surpassed all of the economic screens and has a positive lifecycle cost. To minimize the cost of the energy-efficiency measures, they were integrated right into the form of the building. This integration significantly reduced the costs and could only be achieved through an integrated design process and with energy efficiency and sustainability as key project objectives in the project charter.

Predesign

Integrated design process

One year prior to the selection process, a delegation from Manitoba Hydro toured Europe to visit exemplars of energy-efficient design and architectural excellence. During the tour, Manitoba Hydro was introduced to a European climate engineer who would later be selected as the energy/climate consultant for the project. The principal of this engineering firm continues to be amazed at how “unusual it was to have a client who educated himself on such a high level before looking for architects and engineers.”

The most notable aspect of the design and build process is that it was conducted within the framework of a formal integrated design process (IDP) that was mandated by Manitoba Hydro and modeled on the successful C-2000 program developed by Natural Resources Canada (NRCan), a department of the Canadian federal government. A representative from NRCan monitored the IDP and assessed the application under the Commercial Building Incentive Programme (CBIP). Manitoba Hydro hired an advocate architect responsible for urban design integration as well as the documentation and submission for LEED program, in which the project achieved a Gold rating.

In contrast to the conventional RFP process, in which the architects propose the consultant team, Manitoba Hydro limited the selection to the design architect first, conducting an intensive international search. The design architect was selected from a 3-stage process and was then required to assist the client in forming the integrated design team, including executive architects, energy engineers, the mechanical and electrical engineers, construction manager, and costing/quantity surveyors.

Design

Investing two years in design

Manitoba Hydro dedicated one full year to the development of the schematic design concept, organized around monthly workshops and design charrettes. Year two was committed to the development of the design and involved a schedule of bi-weekly meetings to ensure all issues—architectural, structural, energy performance, cost, constructability, LEED, etc.—were fully integrated in the final design solution. Key milestones included four design charrettes to explore and test 16 alternatives, select three options for testing, and a final concept for development.

The first IDP Session was held off site to clarify and agree upon principal goals. These were then summarized in a three-page project charter and signed by Manitoba Hydro’s executive and all IDP members. The charter established the following integral goals and generated a sense of ownership among all involved.

-Supportive workplace: healthy and effective contemporary office environment for 2,000 employees adaptable to changing technology and workplace environment for present and future needs

-World-class energy efficiency: target 60% greater energy efficiency than Canada’s Model National Energy Code for Buildings (MNECB)

-Sustainability: LEED Gold Certification

-Signature architecture: design to celebrate the importance of Manitoba Hydro to the province and to enhance the image of downtown Winnipeg

-Urban regeneration: strengthen and contribute to a sustainable future for Winnipeg’s downtown

-Cost: Cost-effective, sound financial investment

-Advocate architects used the charter as a gauge throughout all phases to keep goals balanced and provide an alternative to the conventional client-architect-engineer contract in which goals are often unclear or undefined.

Construction

As a city of 500,000, Winnipeg’s labor and trades had limited experience in building large-scale office towers. In 2005, the regional building market was overheated due to the boom in western Canada and several large infrastructure projects proceeding on a similar timetable. The construction manager and cost consultant identified the difficult market conditions as the most significant risk factor for Manitoba Hydro. Their advice was to get to the market quickly before the other large projects by using a fast-track, sequential bid process.

Schematic design was completed in May 2005 and construction began in August 2005. Every major package—structure, curtainwall, exterior wall skin, MEP—was developed as a “design-assist” package. Documents were advanced in sequence to a design development level for trades to bid using a guaranteed maximum price (GMP) pricing system. The selected trade then worked with the consultants to finish the development of the package and proceed into shop drawings and construction. The last package, soft landscaping, was tendered in Fall 2007 as the concrete structure was nearly topped out. Substantial completion, originally intended for Spring 2008 , was completed in Winter 2008.

There was a significant risk that the fast-track design-assist process might not be able to deliver on the necessary quality to achieve the charter goals. The IDP allowed the consultant team and the construction manager to develop a trusting relationship and a truly integrated team from the start. The construction manager was able to rely on the consultants to help formulate scopes of work that took into account that the documents were not complete nor fully coordinated with other consultant packages still in formation. Each package went through a process of tendering, value engineering, and completion of documentation while the trade was on board. As other major packages were issued, the early packages were coordinated with this work and Issued for Construction packages were issued. Trades compared initial packages to final packages and identified scope and cost changes.

Both the construction manager and the architect of record maintained meticulous records of each package in their various iterations. Regularly scheduled production meetings face-to-face and via teleconference continued the spirit of the IDP through construction. The team, including the client, avoided the “blame game,” recognizing the leap of faith that everyone took in working with design development-level documents to begin each phase of construction and the process of completing each set of documents and tracking the coordination, changes, and updates not only in the document sets but also on the construction site.

Operations/Maintenance

Manitoba Hydro hired the future building operators midway through the project and added them to the project team. This enabled them to have a firsthand understanding of the building’s systems and future maintenance requirements.

To reflect the building’s minimal active mechanical systems and optimized passive systems, the operations team includes an energy management engineer and a building controls specialist. With over 20,000 control points interacting with a weather station located on the roof, operations/maintenance has a dramatically different look.

A comprehensive energy management plan has been incorporated into the daily operations and maintenance processes.

Commissioning

A complete commissioning plan was developed by an independent, third-party commissioning agent. The plan was developed in accordance with current best practices, and was put in place to ensure that the building was designed, constructed, and operated as intended. The commissioning agent was involved early in the design phase, and conducted reviews of the basis-of-design, construction, and equipment submittal documents. As the project transitioned into the construction phase, the commissioning agent used a three-stage process to ensure proper functioning of building systems. First, an installation qualification check was made to ensure the equipment installation meets current best practices. Second, an operational qualification check was made to ensure that the equipment is fully functional as an isolated piece of equipment. And third, system qualification checks were made to ensure that the equipment fulfils its role and that overall systems are functioning as intended.

The duties of the commissioning agent extended beyond the project completion date. The agent was responsible for educating the facilities group and providing documentation to ensure proper operation and maintenance of the building. The commissioning agent was also responsible for ongoing commissioning and setting up requirements for re-commissioning in the future.

While the independent commissioning authority was responsible for the majority of the project scope, there were several specialized commissioning authorities. These included an independent curtainwall expert to perform commissioning of the building façade, and commissioning of the specialized lighting system. In addition, future Manitoba Hydro building operations staff were added to the commissioning team to gain firsthand knowledge of all building operations and sequences.

Post-Occupancy

A comprehensive collection of meters have been installed at Manitoba Hydro Place to allow for the verification and optimization of the energy targets. The metering list includes main utility meters and a variety of sub-meters for lighting, plug loads, water heating, HVAC energy, and tenant spaces. In addition, plant systems can be monitored for overall efficiency. These meters are tied into web-based energy management software for storage and analysis.

An in-depth measurement and verification plan was developed by the building energy management engineer, a full-time position on the facilities team at Manitoba Hydro. The plan is consistent with the International Performance Measurement and Verification Protocol (IPMVP) and focuses on developing an as-built model of the building. This calibrated model will be used as a reference for actual, metered data. The plan encompasses a two-year post-commissioning period. An energy advisory team has been initiated, consisting of building energy experts and members of the design team, for the purpose of studying the building and ensuring that the actual building performance meets or exceeds the design model. This process also allows for the engineering team to evaluate the accuracy of their energy-efficiency design models and recalibrate as required based on the building’s actual performance. This information is vital for the advancement of energy-efficient green building technologies.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect | Luigi | LaRocca | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | John | Peterson | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Kael | Opie | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Lucy | Timbers | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Glenn | MacMullin | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Ramon | Janer | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Javier | Uribe | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Taymoore | Balbaa | Kuwabara Payne McKenna Blumberg Architects | Toronto, Ontario |

| Architect | Jim | Yamashita | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Rick | Linley | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Glen | Klym | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Al | Coppinger | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | John | Crocker | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Colin | Reed | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Ron | Pidwerbesky | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Kirk | McLean | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Charlene | Kroll | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Daryl | Hnylycia | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Sheila | Reenders | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Architect | Lynne | Richardson | Smith Carter Architects and Engineers | Winnipeg, Manitoba |

| Energy consultant | Thomas | Auer | Transsolar Energietechnik | |

| Energy consultant | Alex | Knirsch | Transsolar Energietechnik | |

| Architect | Dudley | Thompson | Prairie Architects | Winnipeg, Manitoba |

| Architect | Crystal | Bornais | Prairie Architects | Winnipeg, Manitoba |

| Structural engineer | Tom | Malkiewicz | Crosier Kilgour & Partners Ltd. | Winnipeg, Manitoba |

| Structural engineer | Joel | Smith | Crosier Kilgour & Partners Ltd. | Winnipeg, Manitoba |

| Structural engineer | Barry | Chamish | Halcrow Yolles | Toronto, Ontario |

| Structural engineer | David | Gray | Halcrow Yolles | Toronto, Ontario |

| Mechanical and electrical engineer | Earth Tech Canada | Burnaby, British Columbia | ||

| Lighting designer | Pivotal Lighting Design | Seattle, WA | ||

| Landscape architect | Glen | Manning | Hilderman Thomas Frank Cram | Winnipeg, Manitoba |

| Landscape architect | Garry | Hilderman | Hilderman Thomas Frank Cram | Winnipeg, Manitoba |

| Landscape architect | Greg | Smallenberg | Phillips Farevaag Smallenberg | Vancouver, British Columbia |

| Landscape architect | Jeff | Staates | Phillips Farevaag Smallenberg | Vancouver, British Columbia |

| Fire Protection and Building Code engineer | Jonathan | Rubes | Leber Rubes | Toronto, Ontario |

| Fire Protection and Building Code engineer | David | Syrett | Leber Rubes | Toronto, Ontario |

| Building Envelope consultant | Mark | Brook | Brook Van Dalen & Associates | Nepean, Ontario |

| Vertical Transportation consultant | Jon | Soberman | Soberman Engineering | Toronto, Ontario |

| Acoustic consultant | Aercoustics Engineering, Ltd. | Toronto, Ontario | ||

| Energy consultant | RWDI | Montreal, Quebec | ||

| Quantity surveyor | Isaac | Gwendo | Hanscomb Limited | Winnipeg, Manitoba |

| Water architecture | Dan | Euser | Dan Euser Water Architecture, Inc. | Toronto, Ontario |